In line with our business foundations of delivering quality products, we have employed a four-layered quality assurance procedure at our production facility described below:

The quality assurance procedure starts right away with the procurement of steel scrap. Once the scrap reaches our production facility, we hire a SGS Team (The Swiss Company that provides inspection, verification, and test services for the material), to ensure the quality of scrap within defined International Standards.

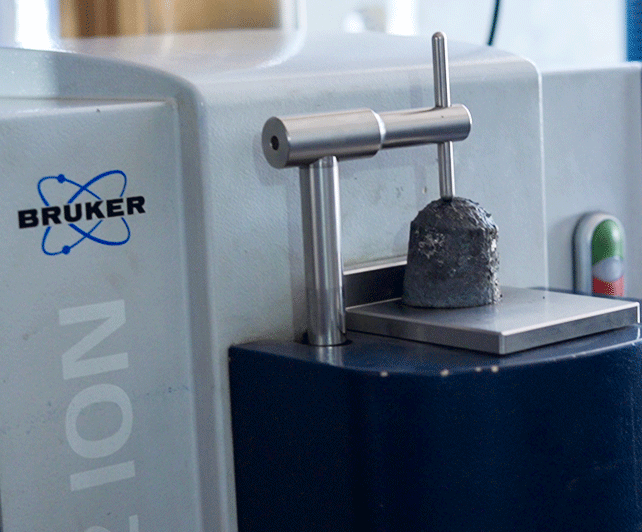

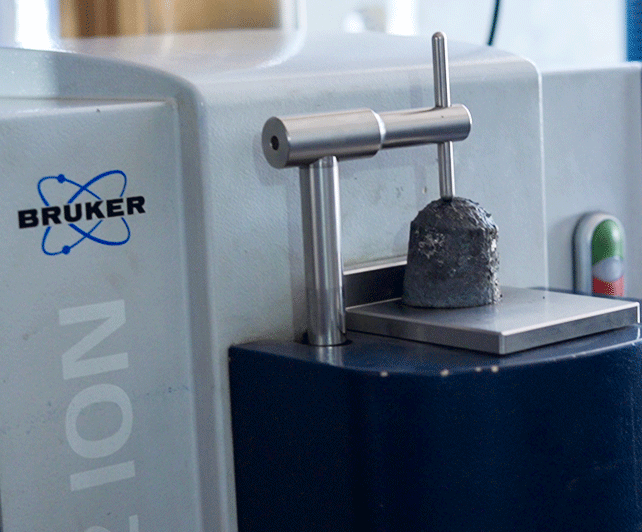

After a satisfactory material report from the SGS team, scrap is melted in an Induction furnace. Multiple samples are taken from molten steel to test the chemical composition of material on a Spectrometer. The test results are fed to the production team to adjust for the sensitive changes in steel composition where necessary.

After a satisfactory material report from the SGS team, scrap is melted in an Induction furnace. Multiple samples are taken from molten steel to test the chemical composition of material on a Spectrometer. The test results are fed to the production team to adjust for the sensitive changes in steel composition where necessary.

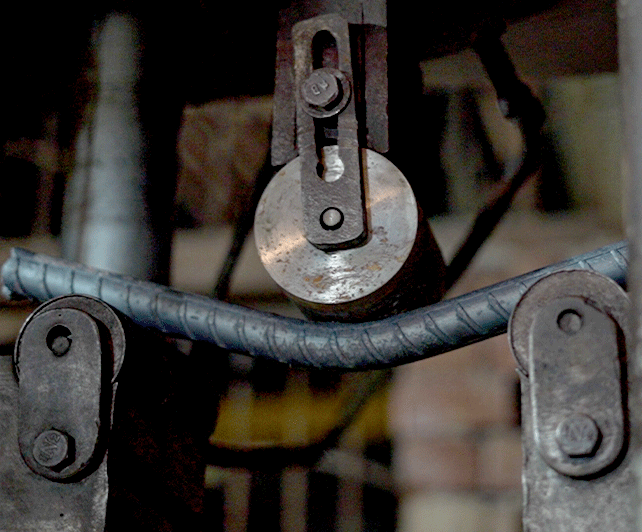

Once the molten steel is solidified into billets and rolled into steel bars, samples are drawn from the finished steel bars for mechanical testing. Samples are mainly tested for yield, tensile, and elongation of the material on the UTM machine at our well-equipped lab.

Once the testing has taken place in three stages, our quality team gives the final approval for the dispatch of material at the loading yard. This is the most important stage of the whole production process; therefore, we have hired the most skilled and qualified human resources to ensure that only quality material leaves our factory premises.

Once the testing has taken place in three stages, our quality team gives the final approval for the dispatch of material at the loading yard. This is the most important stage of the whole production process; therefore, we have hired the most skilled and qualified human resources to ensure that only quality material leaves our factory premises.